PTFE Coating Fiber Glass Filter Felts

Commodity

Description:

We use best fiberglass fiber to make filter felts , finishing coating it with fine PTFE, then make it into various of Teflon high temperature resistance filter felts in different thickness and width.

Advantages:

• Chemical inertness: Affected only by a few rare substances at very high temperatures

• High release from sticky materials ‘non-stick’

• Easy cleaning (nothing bonds permanently)

• Low friction coefficient: 0.04 - 0.10; depending on load and surface speed

• Chemical corrosion and moisture resistance

• Mildew and fungus resistance

• Outstanding electrical and dielectric properties

• Ultra-violet, Infra-red, microwave & radio frequency resistance

• Non combustible - self extinguishing

• Low thermal expansion: < 5%

Application:

Steel, Metallurgy, Cement, Power, Chemical, Paint, Dye Petroleum Refining, Food, Pharmaceutical, Galvanic Asphalt mixer plant; Dust Treatment, Building wastage, Waste Incineraors, Profiteering Solvent; Chemical Corrosion, Coal-fired boilers,Gas Collection, Blast Furnace, Valble Dust

Glass FIBER

To meet operating conditions of different customers processes we choose a wide range of first class glass fibers with variable resistance to high temperature, to highly corrosive and oxidative environments.

The most common fibers for needle felts production are PES, PP, PAN, meta-aramid, PPS, PI, PTFE ,fiberglass

To optimize the performance, different fibers with different counts and shapes can be combined (ex. PTFE combined with P84®).

●PP = polypropylene

●PES = polyester

●PPS = polyphenylenesulphide

●MA = meta-aramid

●PI = polyimide

●PTFE = polytetrafluoroethylene

NOTE: Indicative values of maximum working temperatures; contact us for details on your specific operating conditions

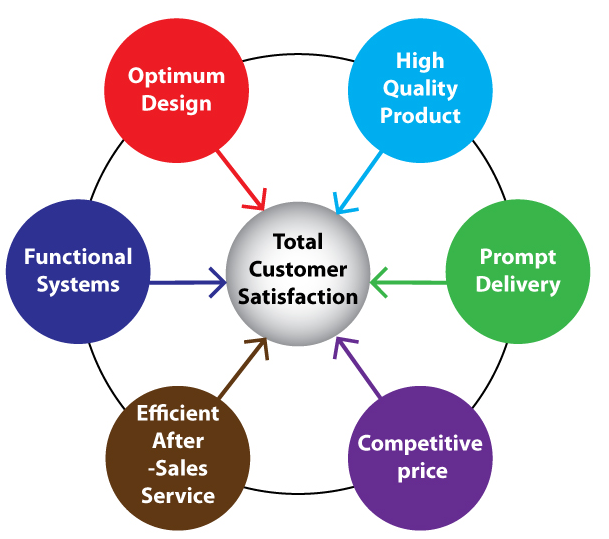

Service Goal

According to professional experience and scientific data, select proper filter material for different working condition. According to the different performance of fiber, use different technical plans to produce precision ,special and more economic filter material.

Supporting customer making bag replenishment plan and filter bag failure analysis through one –line inspection