High Temperature Fire Resistance Meta Aramid Dust Collector Bags

Commodity

High Temperature Fire Resistance Meta Aramid Dust Collector Bags

Description

High Temperature Fire Resistance Meta Aramid Dust Collector Bags has features of abrasion resistance, easy hydrolysis, good flame retardation.

Material: aramid (Nomex) fiber, supported with aramid (Nomex) scrim / fabric.

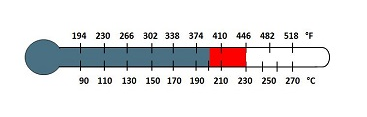

Continuous working temperature: 204 degree C

Max working temperature in short time(within 5 minutes): 230 degree C

Weight range: 350-600gsm

Common weight: 450gsm, 500gsm, 550gsm, 600gsm

Normal treatment: singed, calendered and heat set

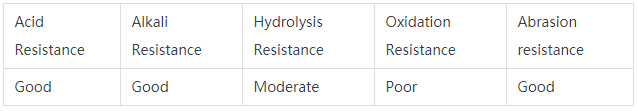

Chemical properties:

MAXIMUM CONTINUOUS IN DRY CONDITIONS: 200°C / 392°F

MAXIMUM SURGE IN DRY CONDITIONS: 230°C / 446°F

APPLICATIONS :

Nomex Filter Bags are mainly used in cement industry, asphalt industry, metallurgical

industry and tobacco industry for flue gas purification.

• Tail gas/fume/dust from metallurgical plant

• Asphalt mixing plant smoke filtration

• Carbon black plant, iron works ( Steel Mill blast furnace gas Filter )

• Cement plant ( tail gas from vertical kiln),

• Petroleum fumes from mixing round the beton and asphaltum

Detergent plant

Advantage

Felt Design & Specifying

Filtration is a very complex, technically-involved business where a multitude of factors need to be taken into account when designing systems: temperature, gas velocity, chemistry, dust characteristics and particle size distribution etc.

Our experienced team of technologists can interpret these parameters and design specific filter media to handle the most demanding applications.

Felt Manufacturing

Being a company with well over 20 years of history we have evolved our processes and technologies to the point where we actually specify our manufacturing equipment to optimize the quality of the finished product. Continued investment ensures that the equipment meets the latest requirements for product uniformity and performance.

Material Finishing & Treatments

High performance needle felts for filtration require more technology than simply producing textiles. The materials almost always require heat stabilization and frequently the surface finish needs to be modified to assist with cleaning.

One must also consider the environment in which the products are to operate so a range of treatments has been developed to assist in filtration. Many are based on fluorocarbon technologies to provide a host of benefits including increased dust collection, enhanced resistance to aggressive chemicals, liquid repellency and spark blocking.