Description:

Many dusts are prone to the build-up of static electricity. Flour is perhaps one of the best known. Historically explosions from handling powder in them were fairly common.

To reduce these dangers,anti-static polyester filter media were developed, allowing the dissipation of any charge which may have built up on the filter bags.

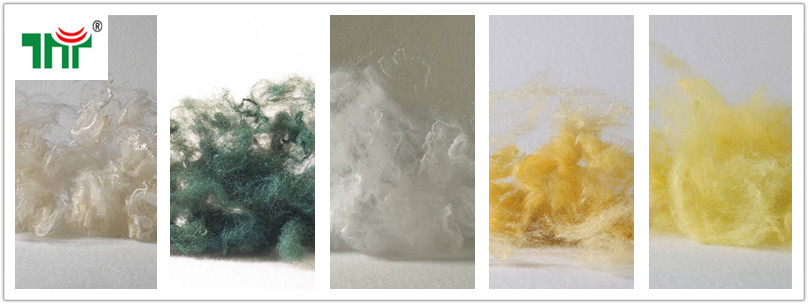

The technology is based on the incorporation of electrically conductive scrim into the needlefelt. The conductive scrim ensures conductivity throughout the felt through the grid pattern inside the material. Several fibers are used to impart static dissipation, the most reliable is stainless steel as this has excellent thermal and chemical resistance and so can withstand all the conditions which the fibers can handle.

Conductivity can also be imparted into the material by using conductive fibers blended into the fiber mix of the felt. The anti static scrim design is preferred as it provides higher consistency of conductivity and a lower cost over the traditional blended conductive fiber products.

Filtration is a very complex, technically-involved business where a multitude of factors need to be taken into account when designing systems: temperature, gas velocity, chemistry, dust characteristics and particle size distribution etc.

Our experienced team of technologists can interpret these parameters and design specific filter media to handle the most demanding applications.

Being a company with well over 20 years of history we have evolved our processes and technologies to the point where we actually specify our manufacturing equipment to optimize the quality of the finished product. Continued investment ensures that the equipment meets the latest requirements for product uniformity and performance.

High performance needle felts for filtration require more technology than simply producing textiles. The materials almost always require heat stabilization and frequently the surface finish needs to be modified to assist with cleaning.

One must also consider the environment in which the products are to operate so a range of treatments has been developed to assist in filtration. Many are based on fluorocarbon technologies to provide a host of benefits including increased dust collection, enhanced resistance to aggressive chemicals, liquid repellency and spark blocking.

Filter Bags Production Equiment

Inspection Equipment Of Finishing Filter Material

Address: ADDRESS: NO.6 Chuangxin 4TH Road,Science And

Technology City,Economic Development Zone,Fushun Liaoning China

Phone: 86-24-56608606

Email: tianyu-filter@263.net

| |

| Qr code |